Rare earth magnets

Rare earth magnets Specification

- Surface Finish

- Nickel Plated

- Features

- High strength, Durable, Reliable

- Thickness

- Typically 2 mm to 25 mm

- Material

- Neodymium Iron Boron (NdFeB)

- Type

- Rare Earth Magnet

- Structure

- Solid Disc or Block

- Resistant Feature

- Corrosion Resistant

- Usage & Applications

- Industrial Lifting, Motor Assemblies, Electronic Devices, Magnetic Separators

- Demagnetization

- Low susceptibility to demagnetization

- Compliance

- RoHS Compliant

- Grade

- N35, N42, N52 (other grades available)

- Shape

- Round (Disc), Block, and Custom shapes

- Coating

- Nickel, Zinc, Epoxy, or Custom

- Customization

- Available as per requirements

- Working Temperature

- Up to 80°C (standard), higher grades available for up to 200°C

- Magnetization Direction

- Axial or Diametrical

- Pull Force

- Varies by size, up to 100 kg

- Density

- Approximately 7.5 g/cm³

Rare earth magnets Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 20 Pieces Per Week

- Delivery Time

- 1 Week

About Rare earth magnets

Exceptional Applications and Competitive Advantages

Rare earth magnets are the premier choice for industrial lifting, motor assemblies, electronic devices, and magnetic separators. Their towering strength, wondrous durability, and corrosion resistance deliver unmatched reliability in various settingsfactories, laboratories, commercial machinery, and electronics fabrication. As direct exporters, importers, and leading suppliers in India, our magnets stand out for their sensational quality, tailored specifications, and swift service. Trust in proven technology that elevates efficiency and performance across numerous industries.

Certifications, Supply Ability, and Sample Policy

All magnets comply with RoHS standards, ensuring environmentally responsible sourcing. Boasting ample supply ability, we efficiently accommodate bulk orders and rapid transportation worldwide. Our transparent quotation process and competitive offer guarantee value for every client. We provide sample options upon request, enabling product trials before placing larger orders. Our customer-centric approach brings reliability, convenience, and prompt deliverymaking us a trusted partner for sourcing high-quality rare earth magnets in India and beyond.

FAQs of Rare earth magnets:

Q: How can I customize rare earth magnets for my specific requirements?

A: Customization is available for shape, size, magnetization direction, coating, and working temperature. Simply share your application details, and our team will provide a tailored solution.Q: What are the primary benefits of using these rare earth magnets?

A: These magnets offer towering strength, wondrous durability, high pull force, corrosion resistance, and low demagnetization, making them ideal for demanding industrial and electronic uses.Q: When should I opt for a higher working temperature grade magnet?

A: Choose a higher working temperature grade if your application involves exposure to heat above 80C. We supply grades suitable for temperatures up to 200C to ensure reliable performance.Q: Where are your rare earth magnets commonly used?

A: Our magnets are widely used in industrial lifting, motor assemblies, electronic devices, magnetic separators, and other applications requiring strong, reliable magnetic force.Q: What is the process for ordering and receiving a quotation?

A: To receive a quotation, provide your magnet requirements (shape, size, grade, coating, and quantity). We will respond promptly with pricing and transportation details, ensuring a smooth order process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyors Category

Suspended Permanent Magnet

Minimum Order Quantity : 1 Piece

Speed : Stationary (Nonmotorized)

Structure : Other, Rectangular

Material : Stainless Steel, Highintensity Magnets

Power Source : Permanent Magnet (No external power required)

Surface Finish : Polished

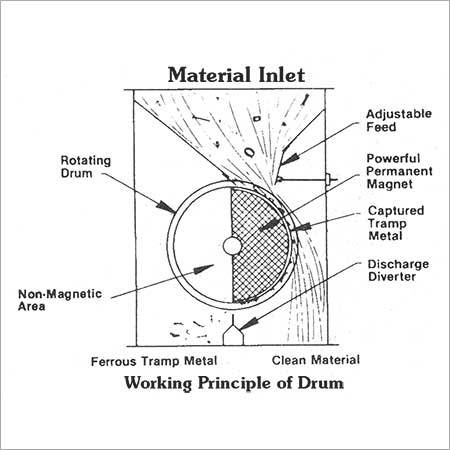

Magnetic Drum Separator Working Principle

Minimum Order Quantity : 1 Piece

Speed : 20 60 RPM

Structure : Other, DrumType, Stationary Magnet

Material : Mild Steel / Stainless Steel

Power Source : Electric Driven

Surface Finish : Painted / Coated

Over Band Magnetic Separator

Minimum Order Quantity : 1 Piece

Speed : Adjustable

Structure : Other, Stationary

Material : Stainless Steel (SS304/SS316), Mild Steel

Power Source : Electric

Surface Finish : Painted / Powdercoated

Trough Belt Conveyors

Minimum Order Quantity : 1 Piece

Speed : 0.5 to 2.5 m/s

Structure : Other, Mild Steel / Stainless Steel Frame

Material : Mild Steel, Stainless Steel, Rubber Belt

Power Source : Electric

Surface Finish : Powder Coated / Painted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS